Precision Stamping Tool/ Die for computer Part

Precision Stamping Tool/ Die for computer Part

| Payment Type: | L/C,T/T,Western Union |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 25-30 Days |

| Packaging: | Standard exported Wooden box packed, Fumigation process(upon required) |

|---|---|

| Brand: | DoHform |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | Kunshan,China |

| Port: | Shanghai,Ningbo,China |

Click on the follow link to find out more information: https://www.dhform.com/nb-notebook-structural-parts/

Company Info

- Company Name: DongHui Mold Machinery Co.Ltd

- Representative: Ding Huan Chen

- Product/Service: Injection Molds , Plastic Moulds , Metal Stamping Dies , Mass Production Injection Molding , Metal Stamping Parts Processing , Mold Base

- Capital (Million US $): US$1 Million - US$2.5 Million

- Year Established: 2010

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 51% - 60%

- No. of Production Lines: 50

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 5,000-10,000 square meters

- Factory Location: No.298 Jianlin Road,Zhangpu Town,Kunshan City,215300,Suzhou,Jiangsu Province, China.

- Contact Person: Mr. Chan

- Tel: 86-512-57999246

Premium Related Products

Hot Products

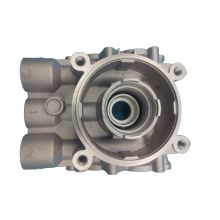

CNC machine aluminum alloy die casting machine partsXiangyu metal manufacturer aluminum die casting parts computer parts/laptop standHigh Quality Lower Price Aluminum Alloy Motocycle Partsaluminum alloy die casting parts metal door lock handlesMost popular high precision motocycle parts diecasting aluminium motor partsdie casting aluminum LED heat sink for LED street light ADC12 heat sinkAluminum alloy die casting parts for LED street light heat sinkModern lamps dinosaur egg lighting 3 heads hanging lamp17mm Die casting parts aluminum profile aluminum tubeSpare Parts 26cc grass trimmer and bruch cutter crankcaseGarden Tool parts, P-Handle for Brush Cutter and TrimmerTOP QUALITY!!High Power Waterproof 50w led street lampAluminum garden tool grass trimmer hedge trimmer China supplierCasting Parts Aluminum High Precision Gear BoxHigh Quality Garden Power Tools Chainsaw Spare parts Chain saw CylinderWholesale aluminum heat sink led housing